Crankshaft Deflection Gauge Winters

GZ Industrial Supplies Nigeria is the distributor of Winters Measuring Instruments in Nigeria. This Crankshaft Deflection Gauge Winters enables the user to check the bearing alignment and deflection of the crankshaft, the deflection gauge shows the distance between adjacent crank webs, which are read at different angular positions of the shaft. Crankshaft should be rotated in one direction, and readings are taken at the defined angular locations. Crankshaft deflections should always be taken on an engine at ambient temperature and compared to the baseline measurements.

The robust construction and the hardened measuring tips make it possible to use the instrument on all kinds of engines. The deflection gauges can also be used to measure and indicate cylinder wear.

If the deflection is measured after an interval of time, it is both important and necessary that it is taken at the same point otherwise the reading will not give a real reflection about the degree of deflection. The ends of the indicator should rest in the punch marks in the crank webs. If these marks are not present, they must be made so that the indicator may be placed in its correct position. Normally a centre punch is used to make markings so that each time the deflection is taken at the same point. Ideally the deflection needs to be taken at four points of the crank namely top, bottom and the two sides.

Features of Crankshaft Deflection Gauge Winters

To check alignment and delflection on all types of engines

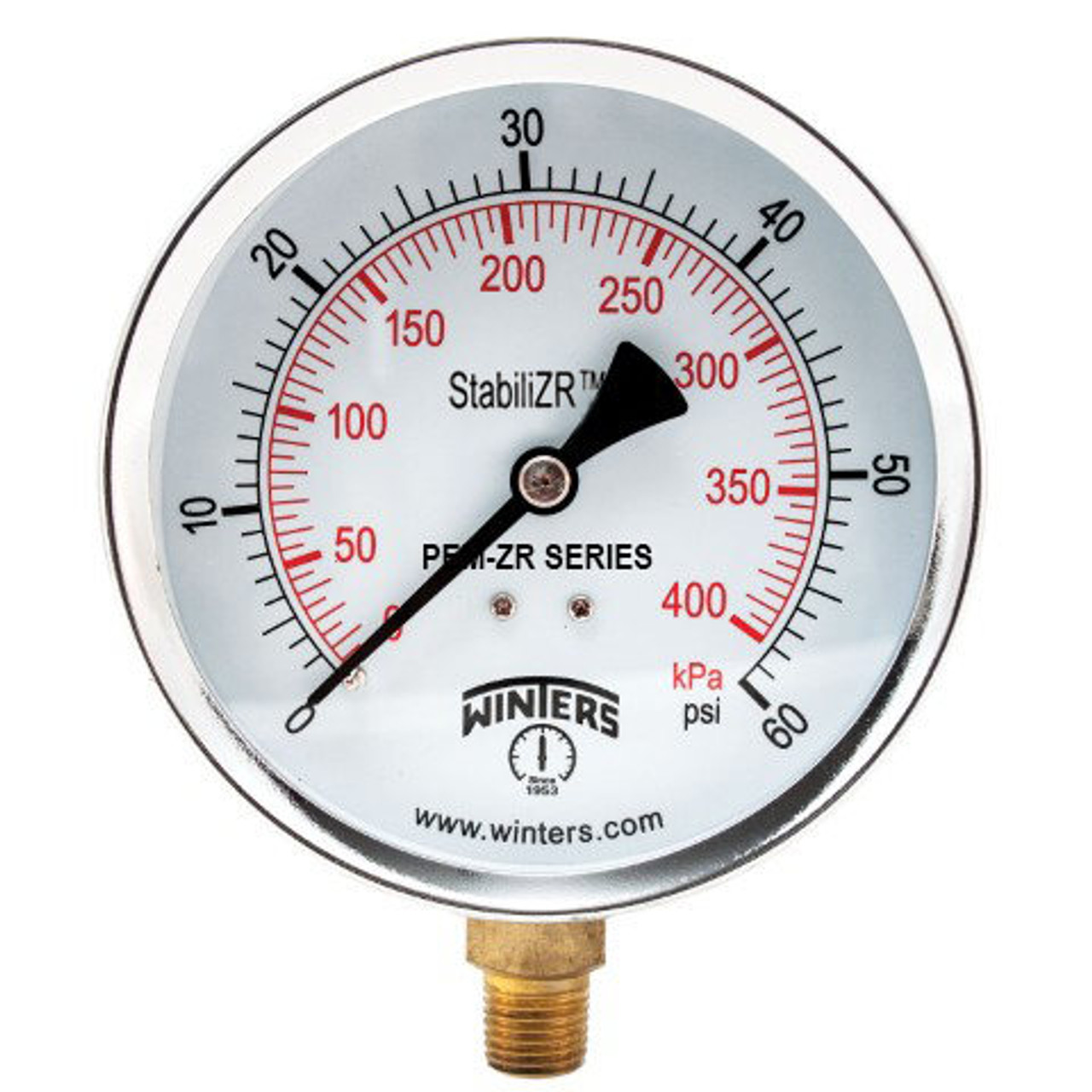

StabiliZR™ dampened movement minimizes effects of pulsation and vibration

Most economical, all-purpose pressure gauge

1.5” (40mm) to 4” (100mm) sizes

Friction bezel rings

Black steel case

Brass wetted parts

ASME B40.100 compliant (EN837-1 available)

±3-2-3% accuracy

CRN registered

5 year warranty

Easy adjustment of gauge position

Compact and robust construction

Ready to use package with case

Precision technology.

Technical Specifications of Crankshaft Deflection Gauge Winters

Dial

1.5” (40mm), 2” (50mm), 2.5” (63mm), 4” (100mm) white aluminum with black and red markings

Case

Steel, painted black (plastic available)

Lens

1.5” (40mm), 2” (50mm), 2.5” (63mm): Acrylic

4” (100mm): Glass

Ring

1.5” (40mm), 2” (50mm): Steel, painted black

2.5” (63mm), 4” (100mm): Steel, chrome plated

Socket

Brass

Connection

1/8” NPT or 1/4” NPT standard

Bourdon Tube

Phosphor bronze

Movement

Brass, StabiliZR™ dampened movement (silicone in sealed chamber)

Pointer

Aluminum, black

Welding

Silver alloy

Over-Pressure Limit

25% of full scale value

Working Pressure

Maximum 75% of full scale value

Ambient/Process Temperature

-40°F to 150°F (-40°C to 65°C)

Accuracy

±3-2-3% ANSI/ASME Grade B

Enclosure Rating

IP52

Contact us for further details and availability within the storefront in your location.

Reviews

There are no reviews yet.