You must be logged in to post a review.

Laryngeal accessories silicone products medical consumables silicone laryngeal processing customization

₦10,115.61

High-quality providers of medical devices and medical accessories! Specializing in providing medical grade silicone injection molding and plastic injection molding,ISO13485Certification!

Main business : Negative Pressure drainage series, anesthesia breathing series, urinary department and gynecology series, silicone balloon and other plastic medical accessories

Cooperation Plan:

1. Mold development and processing: it can be customized with drawings, samples or self-developed and manufactured. We have a large number of equipment to test various indexes of the mold, and we can also process some pre-orders on behalf of the mold until the mold is debugged to the best state and delivered!

2. Mold development+Product Processing (OEM): The mold cost is high, we are willing to share risks with you!!Mold retentionAnd let us process order products on behalf of us,We only charge half of the mold opening fee until the mold cost is recovered!!

Contact Information:

Address: Jiuzhou Avenue, torch development zone, Zhongshan City, Guangdong province5No.

Mobile:+8618024210796 Wechat/Whatsapp/Viber:+86 13699840823

Facebook: Gao Yuan Liao Twitter: @longsun1 Intagram: albert3572

P.M: Albert

Email:gy-bud2(a)gaoyuanchina.com

We are not only developing moulds, but also cooperating with each other is our philosophy. We provide one-stop service silicone mold and products.Welcome to visit, guide and discuss cooperation!

Zhongshan Gaoyuan Technology Co., Ltd.

Zhongshan Gaoyuan Technology Co., Ltd. was established in2007Year12In May, it is located in Torch High-Tech Industrial Development Zone, Zhongshan City, Guangdong province, adjacent to Guangzhou and Shenzhen, with convenient transportation.

Gao Yuan has strong technical strength and is a national high-tech enterprise integrating silicone, plastic mold manufacturing and product design and development. The company has advanced production equipment and a large number of professionals, among which silicone cold runner technology has won many national invention patents, and its high quality has been well received by customers at home and abroad. The company has passedISO9001:2015Quality management system andISO13485:2016Medical Device Quality management system certification, and committedIATF16949:2016The construction of the quality management system of the automobile industry is the Hong Productivity Council (HKPC)Cooperation supplier of silicone products.

The company currently owns about7000m²The production base1000m²100,000-grade clean production workshop and1000m²Mold processing center. We can realize fully automated production and molding, and can provide medical equipment and automobile parts, especially silicone and plastic products of seals.OEM/ODMService.

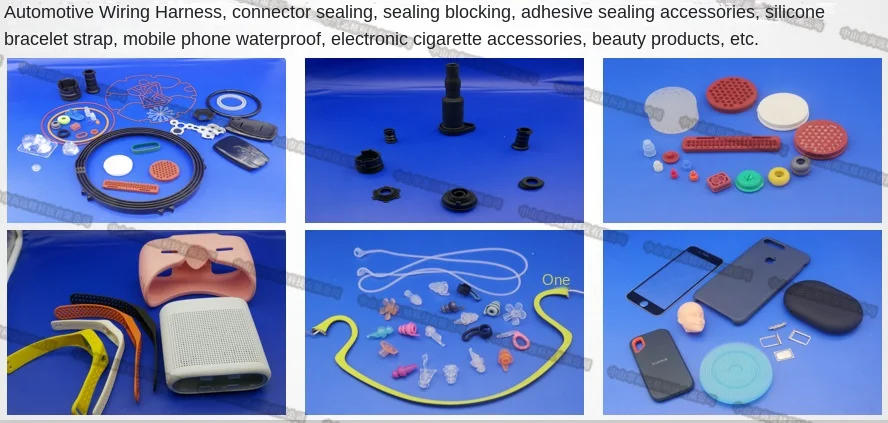

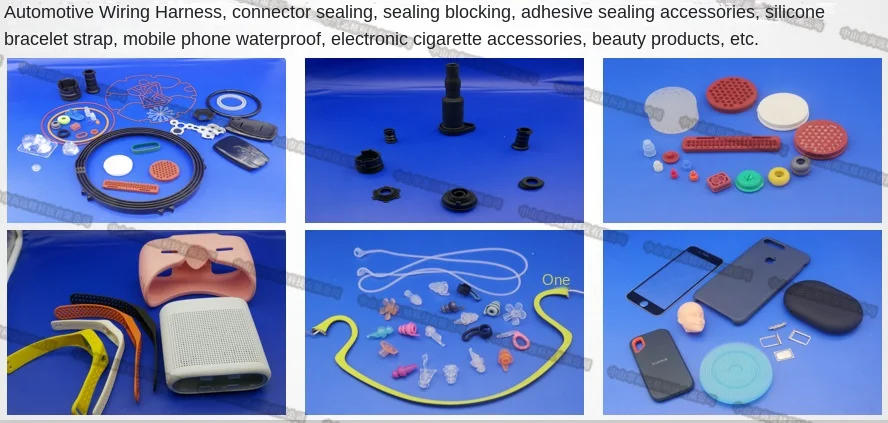

We are committed to becoming a silicone professional solution provider for plastic molding.”! Our products are widely used in many industries such as medical devices, automobiles, babies, optical electronics, kitchenware, sanitary ware, etc. Our partners are all over the world and have established long-term strategic cooperative relations with a large number of well-known brands at home and abroad, such as Medtronic, Intertek, Chinese Academy of Sciences, Mingrui medical treatment, Yuyue Medical treatment, Quanfeng auto parts, yanfeng vishitong, Philips, Fugang electronics, Kohler, Decathlon, dilt,NUKEtc. Through continuous technological innovation and lean management, the company provides customers with better and more efficient products and services. Sincerely look forward to working with our customers to create brilliant future together!

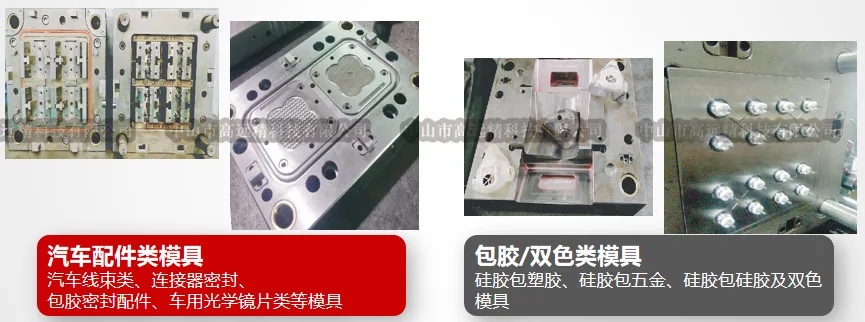

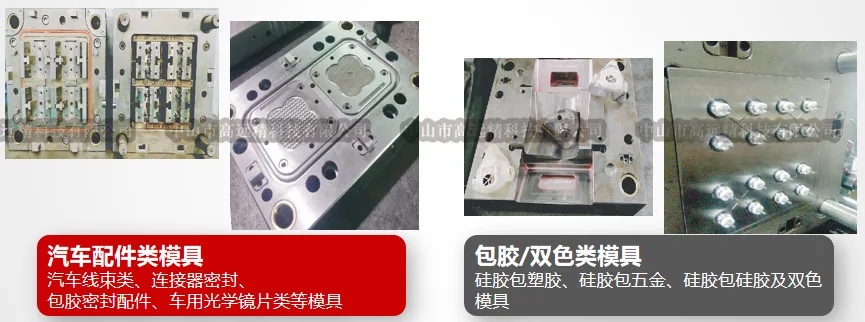

Zhongshan Gaoyuan mould Co., Ltd. With precisionCNC, engraving machine, lathe, numerically controlled grinder, electrical discharge machine, milling machine, silica gel injector, injection molding machine, and other advanced equipment, mature technology, technology, has a complete and scientific production management system.

Molding machine

Features of Gaoyuan silicone mold:

1. Have unique experience in selecting die steel materials, ensuring that the mold cavity will not crack under high mold temperature, the row position will not burn, and the ejection part will move smoothly.

2. Have unique experience in designing the mold exhaust tank to ensure that the mold is not trapped and the product is not short of glue.

3. The heating part of the mold can be heated by heating or water and oil to ensure uniform mold temperature and product quality.

4, can design mold with complex structure, multi-layer mold core push-out, double material mold.

5, good product rate reached95%Above, domestic counterparts can be said to be one of the best.

6. The designed mold can be applied to vertical injection molding machine, horizontal silicone ejector, hot pressing and fluidized.

Medical Accessories

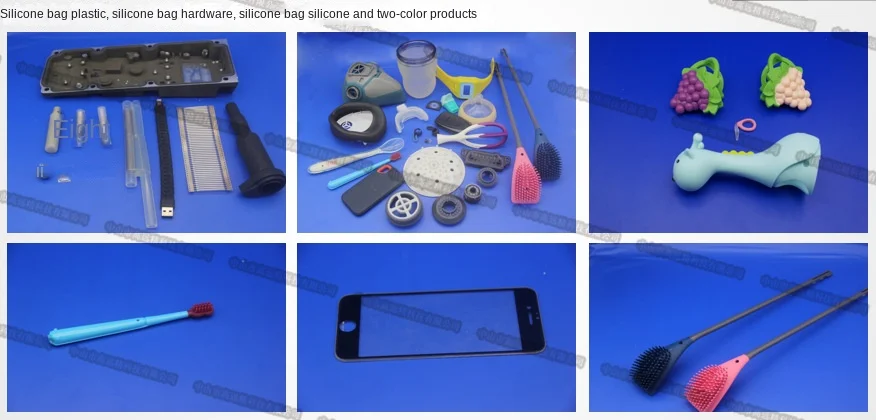

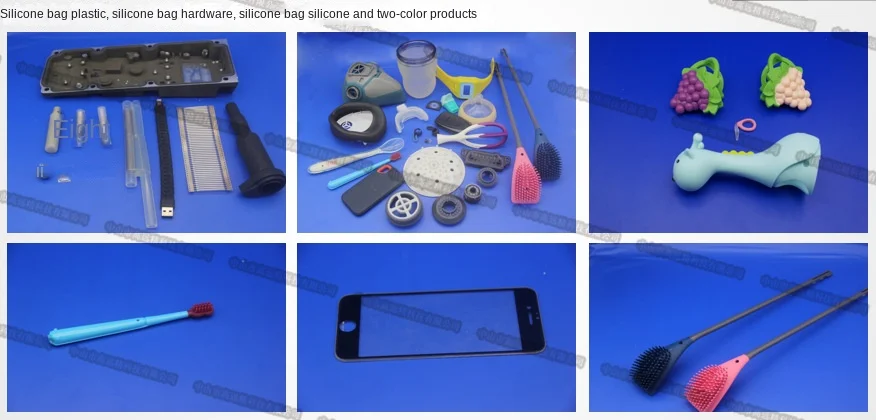

Glue-coated, two-color

Auto parts and electronics

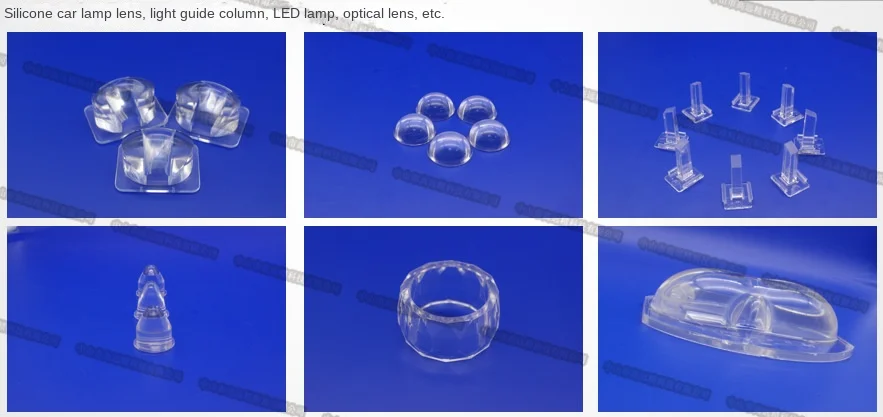

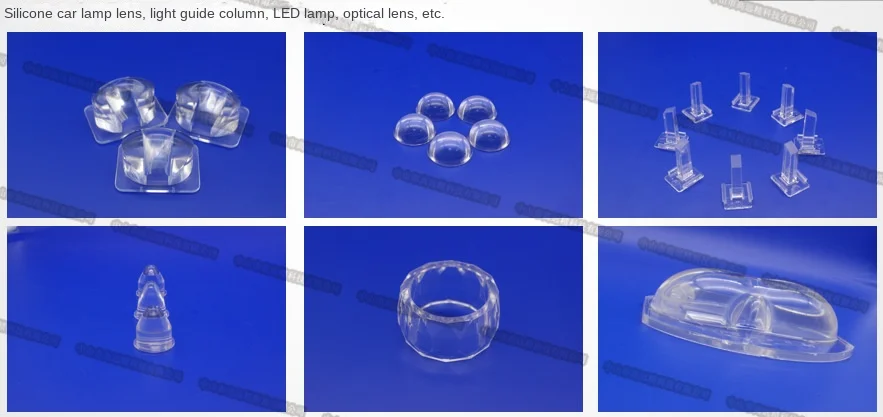

Optics

Baby products

Silicone daily products&Plastic products

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.