Detailed Images

Detailed Images

-

-

Raw Material Polishing

-

High Voltage Resistance Coating

-

Attractive Product Insulation

Product Basics and Information

Diathermy Electrosurgical Instruments are very useful for an effective coagulation and manipulation of biological tissues in electrosurgery procedures, reducing blood loss and transfusion requirements without affecting outcome. With advance technology practices it appears to reduce the risk of damaging external subjects and provide precise performance of working directly on the infected tissues during electrosurgery procedures. The instruments connected with a power source handpiece which is taking current from diathermy electrosurgical machine to provide output of alternative current at the working point for coagulating, grasping and cutting of biological tissues. An extra diathermy patient return electrode mostly being used to return extensive current within the subject toward diathermy electrosurgical machine. Various application has their own unique output frequency and to avoid any hazards only skilled and qualified surgeons are requested to operate the instruments.

Certifications

Certifications

Quality Certificates

Worldwide Shipping

Company Introduction

Company Introduction

When in the 2009, the voluntary opportunity arose to introduce Quality Assurance systems, Electro Range MFG Co. was one of the top 5 company to put these systems into practice. We are optimizing our manufacturing facility as per upcoming MDR 2017/745 standard.

In 2022, we would become one of the first PK companies to achieve an MDR 2017/745 certificate. It is therefore obvious that all our products are subject to stringent Quality Assurance procedures and constant checks during use. Our company is certified in accordance with the following standards: SGS ISO 9001, SGS 13485 and SGS CE Directive 93/42/EEC.

In 2022, we would become one of the first PK companies to achieve an MDR 2017/745 certificate. It is therefore obvious that all our products are subject to stringent Quality Assurance procedures and constant checks during use. Our company is certified in accordance with the following standards: SGS ISO 9001, SGS 13485 and SGS CE Directive 93/42/EEC.

Our Services & Strength

Since October 2006 Electro Range MFG Co has been supplying the Healthcare Industry professionals and distributors with finest quality Electrosurgical instruments and innovative products for Electrosurgery. We are recognized as being amongst one of the most progressive medical companies in the Sialkot. With our extensive wide range of Bipolar Forceps, Electrosurgical Cables, Diathermy Pencils, Patient Return Plates and Electrodes plus with a combination of forefather business experience in the medical field, our products are specifically designed to offer both exceptional quality and value for money to Healthcare Professionals and Organizations. Our in-house ISO and CE Certified manufacturing facility is equipped with latest machineries, experienced professional staff and huge production lines capacity of producing more than 75 Thousand (75K) products per month which allows ERMC to offer fastest delivery time, competitive prices and priority customer services.

Related Products

Related Products

FAQ

FAQ

1. Where does Electrosurgery instruments used?

Answer: Intended to use for open surgery practices design to use for grasping, manipulating and coagulating biological tissues. Most advance feature is the properties of controlled bleeding while being operated at high frequency alternate electrical current and after healing no scars left on the subject.

2. What is difference between Bipolar and Monopolar forceps?

Answer: In bipolar instruments the current flows in two separate poles. Negative Voltages in Pole-1 and Positive Voltages in Pole-2 current flows at the same time but in alternate ways. In Monopolar instruments the current flows in only one pole. Either negative volts or positive volts flows at the same time throughout the instrument.

3. How many times reusable instruments can be autoclave and at which temperature?

Answer: Reusable instruments can be autoclave upto 40 times (followed by defined protocols)

4. How many times reusable cables can be autoclave and at which temperature?

Answer: Reusable cables can be autoclave upto 100 times (followed by defined protocols)

5. How many layers of coating we paste on instruments?

Answer: High voltage and heat resistant 2/3 Layers of powder coating insulation applied to all our forceps to avoid leakage of current throughout the surface of insulated area. But in single use the chemical properties are subject to change after one-time usage.

6. What coating colours we have in reusable and disposable instruments?

Answer: We have colour options for Blue, Black, Orange, Pink and Green.

7. Do we have Bipolar Monopolar diathermy Connecting Cables?

Answer: Yes, our connecting cables are compatible with all famous brands available in market. We also do OEM projects upon respective design and machine compatibility.

8. Do we have standard fitting of connectors in Bipolar and Monopolar instruments?

Answer: Yes

9. What is difference between regular forceps and NON-STICK BIPOLAR FORCEPS?

Answer: During the coagulation of tissues with regular forceps the Coagulated tissues might stick on the tips of the forceps material but with excellent thermal properties for the Non-Stick tips of the forceps, difficult and time-consuming cleaning of the forceps during an operation is no longer necessary and Non-Stick Forceps technology

enables nonstop working.

10. Do we test each and every product?

Answer: Yes, as per our applied QMS standards of ISO 13485 and Directive 93/42/EEC it is mandatory in our routine practice to perform all safety and electric test on every product before proceed them for final packaging.

11. Do we have warranty covering ERMC instruments?

Answer: Yes, we take full responsibility of our products for 1 Year warranty (followed by defined protocols)

Answer: Intended to use for open surgery practices design to use for grasping, manipulating and coagulating biological tissues. Most advance feature is the properties of controlled bleeding while being operated at high frequency alternate electrical current and after healing no scars left on the subject.

2. What is difference between Bipolar and Monopolar forceps?

Answer: In bipolar instruments the current flows in two separate poles. Negative Voltages in Pole-1 and Positive Voltages in Pole-2 current flows at the same time but in alternate ways. In Monopolar instruments the current flows in only one pole. Either negative volts or positive volts flows at the same time throughout the instrument.

3. How many times reusable instruments can be autoclave and at which temperature?

Answer: Reusable instruments can be autoclave upto 40 times (followed by defined protocols)

4. How many times reusable cables can be autoclave and at which temperature?

Answer: Reusable cables can be autoclave upto 100 times (followed by defined protocols)

5. How many layers of coating we paste on instruments?

Answer: High voltage and heat resistant 2/3 Layers of powder coating insulation applied to all our forceps to avoid leakage of current throughout the surface of insulated area. But in single use the chemical properties are subject to change after one-time usage.

6. What coating colours we have in reusable and disposable instruments?

Answer: We have colour options for Blue, Black, Orange, Pink and Green.

7. Do we have Bipolar Monopolar diathermy Connecting Cables?

Answer: Yes, our connecting cables are compatible with all famous brands available in market. We also do OEM projects upon respective design and machine compatibility.

8. Do we have standard fitting of connectors in Bipolar and Monopolar instruments?

Answer: Yes

9. What is difference between regular forceps and NON-STICK BIPOLAR FORCEPS?

Answer: During the coagulation of tissues with regular forceps the Coagulated tissues might stick on the tips of the forceps material but with excellent thermal properties for the Non-Stick tips of the forceps, difficult and time-consuming cleaning of the forceps during an operation is no longer necessary and Non-Stick Forceps technology

enables nonstop working.

10. Do we test each and every product?

Answer: Yes, as per our applied QMS standards of ISO 13485 and Directive 93/42/EEC it is mandatory in our routine practice to perform all safety and electric test on every product before proceed them for final packaging.

11. Do we have warranty covering ERMC instruments?

Answer: Yes, we take full responsibility of our products for 1 Year warranty (followed by defined protocols)

12. Are your products manufacturing in your own facility?

Answer: Yes we have our own state-of-the-art manufacturing facility with huge production capacity of thousand pieces.

Answer: Yes we have our own state-of-the-art manufacturing facility with huge production capacity of thousand pieces.

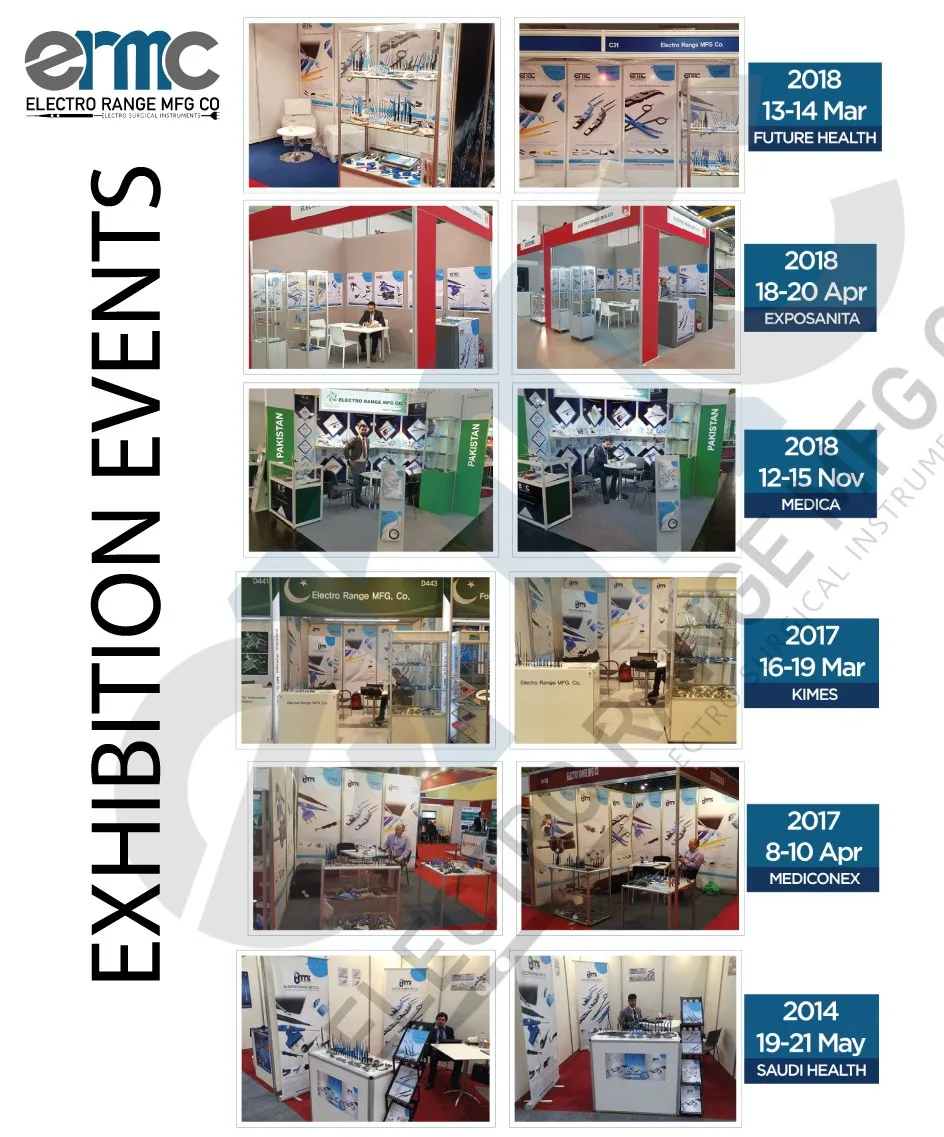

Exhibition

Exhibition

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.