-

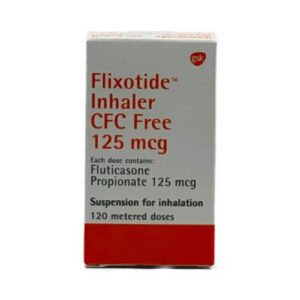

BTR TAB 10`S ₦3,801.50 QTY: 1

Customer matched zone "Lagos Delivery Options"

Sort by:

125665–125680 of 362918 Results

-

SaleSku: 1737140177-8955

FLOVAS 20MG STRIP OF 14 TABLETS

₦9,621.25Original price was: ₦9,621.25.₦7,937.50Current price is: ₦7,937.50.₦9,621.25Original price was: ₦9,621.25.₦7,937.50Current price is: ₦7,937.50. Add to basket Quick View -

-

-

Sku: 1701821421-368

Flow Calibration with Certificate – Available On Request, Prices in Dollars

₦550.03 -

New

-

Sku: 1701821416-367

Flow Controller with One-Touch Fittings, Inline Type – Available On Request, Prices in Dollars

₦87.16 -

Description CS-iTEC FLOW DIRECTONAL SWITCH FOR COMPRESSED AIR AND GASES The thermal mass flow direction switch S 409 allows the detection of an existing flow and the direction of the flow. It can be used in compressed air and non-corrosive gases. The sensor element is very robust and completely of stainless steel. Through a 1/2” G-type ball valve the switch can be inserted into the pipe under pressure. The flow and direction information is output through 2 normally open relay switches. This signals can be transferred to the CS flow sensor to activate and deactivate the flow measurement depending on the flow direction. Application Connection of S 330 to S 450 via flow switch Connection of S 330 to two S 400 with flow switch Product Features Detects smallest changes <0.1 m/s referred to 20 °C and 1000 mbar No mechanical wear parts Easy installation under pressure All parts which are in contact with flow medium are made of stainless steel Technical data Technical data S 409 Detection range 0.1 … 185 Nm/s Sensor 2 x Pt 1000 Medium air, gases Medium humidity <100% (no condensation) Medium temp. -20 … 80 ºC Ambient temp. -20 … 70 ºC Operating pressure 0 … 16 bar Power supply 24 VDC, 60 mA Output 2 x Relay, 60V, 1A Process connection 1/2” G typeSku: 1701821410-366

Flow Direction Switch for Compressed Air / Gases S 409 – Available On Request, Prices in Dollars

₦954.46 -

SaleA pipe network is a system of interconnected pipes used for fluid transport. A pipe network can be used for a variety of purposes, such as water supply, sewage disposal, heating and cooling systems, and industrial process piping. Flow in a pipe network is determined by the principles of fluid mechanics, including conservation of mass and energy, as well as the properties of the fluid and the geometry of the pipes. Here are some common methods used to analyze flow in a pipe network:

- Conservation of mass: The principle of conservation of mass states that the mass of fluid entering a pipe junction must equal the mass of fluid exiting the junction. This principle is used to calculate the flow rates of fluid in the pipes of the network.

- Conservation of energy: The principle of conservation of energy states that the total energy of the fluid in a pipe network must remain constant. This principle is used to calculate the pressure drops and head losses in the pipes.

- Pipe network modeling: Pipe network modeling involves creating a mathematical model of the pipe network using computer software, such as EPANET or Bentley Systems. The model can be used to simulate the flow rates and pressures in the network under different operating conditions.

- Pipe sizing: Pipe sizing involves selecting the appropriate pipe diameter for each section of the network to ensure that the flow rate and pressure drop are within the design specifications.

- Pump selection: Pump selection involves selecting the appropriate pump type and size to provide the necessary flow rate and pressure to the network.

- Flow measurement: Flow measurement involves using flow meters, such as differential pressure meters, magnetic flow meters, or ultrasonic flow meters, to measure the flow rates of fluid in the pipes of the network.

Sku: flow-in-pipe-networkFlow in Pipe Network

₦600,000.00Original price was: ₦600,000.00.₦520,000.00Current price is: ₦520,000.00.₦600,000.00Original price was: ₦600,000.00.₦520,000.00Current price is: ₦520,000.00. Add to basket Quick View -

SaleFlow indicators give precise visual indication of the flow velocity of liquids or gases being transported through hose connections.The impeller starts to rotate at a given flow rate (see details under each individual type).Optional colours for ease of?identification?for different hose lines. Feefo ReviewsSku: 1723931334-407

Flow Indicator Paddles

₦50,000.00Original price was: ₦50,000.00.₦6,880.00Current price is: ₦6,880.00.₦50,000.00Original price was: ₦50,000.00.₦6,880.00Current price is: ₦6,880.00. Add to basket Quick View -

SaleA flow measuring apparatus is a device or system used to measure the rate of flow of a fluid, such as a liquid or gas, through a pipe or conduit. Flow measurement is important in a wide range of applications, including process control, monitoring and optimization of fluid flow, and research in fluid dynamics. Here are some common types and features of flow measuring apparatus:

- Differential pressure flow meters: These flow meters measure the pressure drop across a constriction in a pipe, such as an orifice plate, venturi tube, or flow nozzle, to determine the flow rate. The differential pressure is measured using pressure sensors or a manometer.

- Positive displacement flow meters: These flow meters measure the volume of fluid displaced by a moving element, such as a piston, gear, or rotor, to determine the flow rate.

- Magnetic flow meters: These flow meters use the principle of electromagnetic induction to measure the flow rate of conductive fluids. A magnetic field is generated by coils around the pipe, and the voltage induced in the fluid is proportional to the flow rate.

- Ultrasonic flow meters: These flow meters use ultrasonic waves to measure the flow rate of fluid in a pipe. Ultrasonic waves are transmitted across the pipe and the time of flight of the waves is used to determine the flow rate.

- Thermal flow meters: These flow meters measure the flow rate of gas by sensing the heat transfer between a heated element and the gas stream. The flow rate is proportional to the heat transfer rate.

- Turbine flow meters: These flow meters use a turbine or paddle wheel to measure the flow rate of liquid in a pipe. The rotation of the turbine or paddle wheel is proportional to the flow rate.

- Coriolis flow meters: These flow meters use the principle of Coriolis force to measure the mass flow rate of fluid in a pipe. The fluid is forced to oscillate by vibrating tubes and the phase shift between the input and output signals is proportional to the mass flow rate.

- Volumetric flow meters: These flow meters measure the volume of fluid passing through a pipe over a given time period. Examples include rotameters and variable area meters.

- Portable flow meters: These flow meters are designed to be easily portable and can be used for flow measurement in a variety of applications, including process monitoring and troubleshooting.

Sku: flow-measuring-apparatusFlow Measuring Apparatus

₦650,000.00Original price was: ₦650,000.00.₦550,000.00Current price is: ₦550,000.00.₦650,000.00Original price was: ₦650,000.00.₦550,000.00Current price is: ₦550,000.00. Add to basket Quick View -

Description Flow meter insertion type- VA 520 – Inline flow meter with integrated measuring section, (R 1/4″ DN 8) Flow meter insertion type- VA 520 application-technological features: • Digital interfaces such as Modbus-RTU, Ethernet (PoE) and M-Bus enable connection to higher-level systems such as energy man-agement systems, building management systems, PLC,… • Easy and affordable installation • Units freely selectable via keys on the display m³/h, m³/min, l/min, l/s, kg/h, kg/min, kg/s, cfm • Compressed air counter up to 1,999,999,999 m³ can be reset to “zero” via keypad • Analog output 4…20 mA, pulse output (electrically isolated) • High measuring accuracy even in the lower measuring range (ideal for leakage measurement) • Negligibly small loss of pressure • Calorimetric measuring principle, no additional pressure and temperature measurement necessary, no mechanically moved parts • Comprehensive diagnostic functions can be read out on the display or remote access via Modbus-RTU such as exceeding max./min values °C, calibration cycle, error codes, serial number. All parameters can be read out and changed via Modbus Flow meter insertion type- VA 520 display shows 2 values at the same time: • Present flow in m³/h, l/min,… • Total consumption (counter reading) in m³, l • Temperature measurement Readout values in the display can be rotated by 180°, e.g. for overhead installation Flow meter insertion type- VA 520 with a key stroke: • Reset counter reading • Select units • Zero-point adjustment, leak flow volume suppression Flow meter insertion type- VA 520 options: Bi-directional measurement. Blue or green arrows in the display indicate the direction of flow. A meter reading is available for each flow direction.Sku: 1701821404-365

Flow meter insertion type- VA 520 – Inline flow meter with integrated measuring section, (R 1/4″ DN 8) – Available On Request, Prices in Dollars

₦1,429.08 -

Description Flow meter insertion type-VA 550 – Flow sensor for installation in existing compressed air or gas line of 3/4″ to DN 1000 Flow meter insertion type-VA 550–Special measurement technology features: • 4 values on the display: Flow, total consumption, velocity, tem-perature. Units freely adjustable • All measured values, settings such as gas type, inner diameter, serial number and so on can be accessed via Modbus-RTU • Comprehensive diagnostic functions readable on the display or remote access via Modbus such as calibration cycle, error codes, serial number • Notifi cation in case of exceeding the calibration cycle • Standard version accuracy 1.5% of m.v. ± 0.3% of f.s. • Precision version accuracy 1.0% of m.v. ± 0.3% of f.s • Measuring span of 1 : 1000 (0.1 up to 224 m/s) • Confi guration and diagnosis via display, hand-held device PI 500, PC service software on-site • Gas type (air, nitrogen, oxygen, argon and so on) freely adjust-able via PC service software or external device DS 400, DS 500, PI 500 • Reference conditions °C and mbar/hPa freely adjustable• Zero-point adjustment, leak fl ow volume suppression • Pressure loss negligible Flow meter insertion type-VA 550–Flow sensor mechanical features: • Robust impact-proof aluminium die cast housing for the outdoor area IP 67 • All wetted parts made from stainless steel 1.4571 • Suitable as an insertion version for 3/4″ to DN 1000 • On request with DVGW approval for natural gas (up to 16 bar) • Pressure range up to 50 bar, special version up to 100 bar • Temperature range up to 180 °C• No moveable parts, no wear • Sensor tip very robust, easy to clean • Easy installation and removal under pressure via 1/2″ ball valve • Housing rotatable, display rotatable by 180° • Safety ring for installation and removal under pressure • Depth scale for precise installation Flow meter insertion type-VA 550–Flow sensor Optional: Connection to different Bus systems There are different options available for connection to modern Bus systems: • Ethernet interface (Modbus-TCP) / PoE • M-BUS • Modbus-RTU • Profi bus DP interface (in process) • Profi net interface (in process) • HART (in process)Sku: 1701821396-364

Flow meter insertion type-VA 550 – Flow sensor for installation in existing compressed air or gas line of 3/4″ to DN 1000 – Available On Request, Prices in Dollars

₦3,682.43