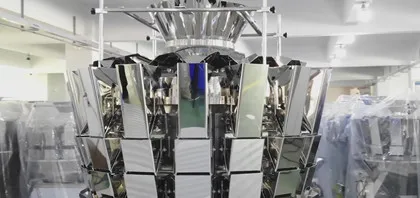

2.Man-machine interface, convenient operation;

3.Tack type, double channel design can increase the counting speeds;

4.100 sets of working parameter settings can be saved, no need to reset if the line change quickly ;

5.Applicable to the demand of different shape products counting; easy to operate;

7.Dust protection cover to ensure hygiene for products;

8.Equipped with conveyor equipment to achieve docking with front and rear equipment;

9.Infrared electronic grain, automatically obtain the sensitivity value and material characteristics, convenient to set parameters.

10.High-speed CAN bus control, easy to expand the number of grain channels.Technical Parameters.

2.Double-channel control unit,which can realize optional switching and independent control of dual-outlet and single-out,which has greater flexibility.

4.The electric gate can realize the rapid interception of materials and ensure the accuracy of the counting.

5.One-button automatic up and down that can realize automatic matching different height of bottles,more intelligent operation.

|

Model

|

JW-SL8

|

|

Identify Code

|

SL8-1-1

|

|

Number of vibrating tracks

|

8

|

|

Drug specifications

|

Φ:5-12mm, L:5-25mm

|

|

Bottle diameter

|

20-100mm

|

|

Bottle height

|

40-240mm

|

|

Speed

|

4000 pcs/min

|

|

Bottle Filling Speed

|

10~60 bottle/min

|

|

Power requirement

|

220V/800W/ 50/60Hz

|

|

Machine dimension

|

1350(L)*1400(W)*1790(H)mm

|

|

Machine weight

|

400kg

|

2.product 2 year warranty period, the industry’s first.

3.more than 1500 global cooperative customers.

4.output of multihead weigher products exceeds 8,000 units per year.

5.Passed CE/PA/MC/OIML and GSG qualification certificate.

6.Participate in more than 20 large-scale industry exhibitions around the world every year.

If there are any special requirements, we will pack according to your requirements.

Delivery:

All our machines are tailor-made because different clients have different requirements, delivery will be within 20 days for the small multihead weigher,For the large-scale machine, it takes longer.

Q1: How to know which one packing machine is suitable for us ?

You can first tell business representative which equipment you want to know, what material is the product, how many grams to weigh, and the range of accuracy and speed requirements. Our engineers then recommend suitable packaging machines based on these data and product characteristics.

Reviews

There are no reviews yet.