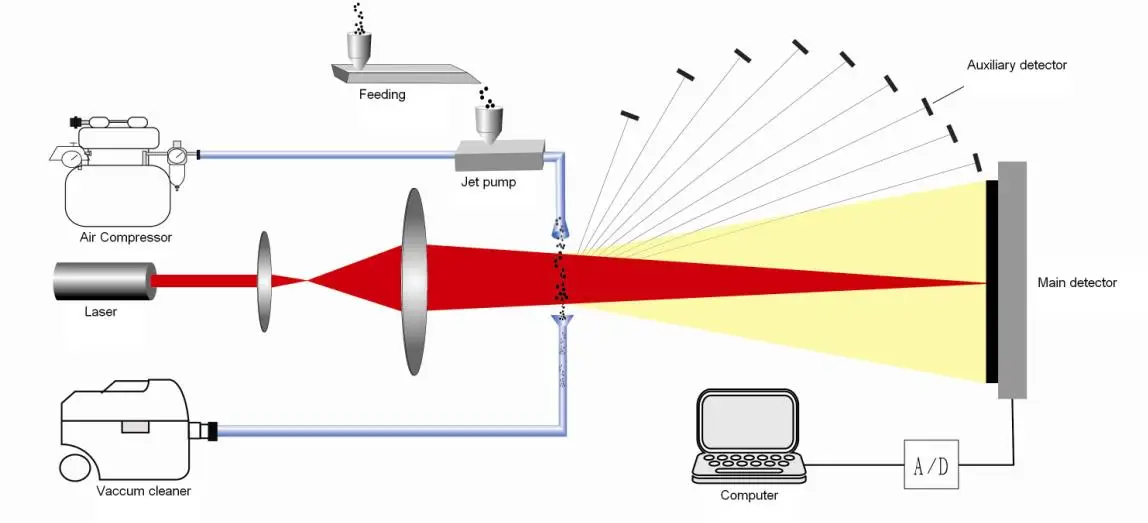

This product uses air as the dispersing medium, the use of turbulent dispersion principle, with high-precision feeding apparatus and Patent powder injection pumps, No-Oil silent air source, ensure that the sample is thoroughly dispersed. It is applied to any powder material, particularly good for materials occurs chemical reaction in water, or shape change in the liquid. It have same accuracy and repeatability compared with the wet method.

1) Unique patent technology of optical path and detection system, greatly improve testing resolution.

2) Scientific and automatic dry dispersing system

Turbulence dispersion patented technology and Normal shock shearing effect make particles sufficient dispersion, dispersion core part using wearable ceramics not only improve dispersion system’s working life but ensure more accurate and stable testing result.

3)Intelligent Operation System realize one key test

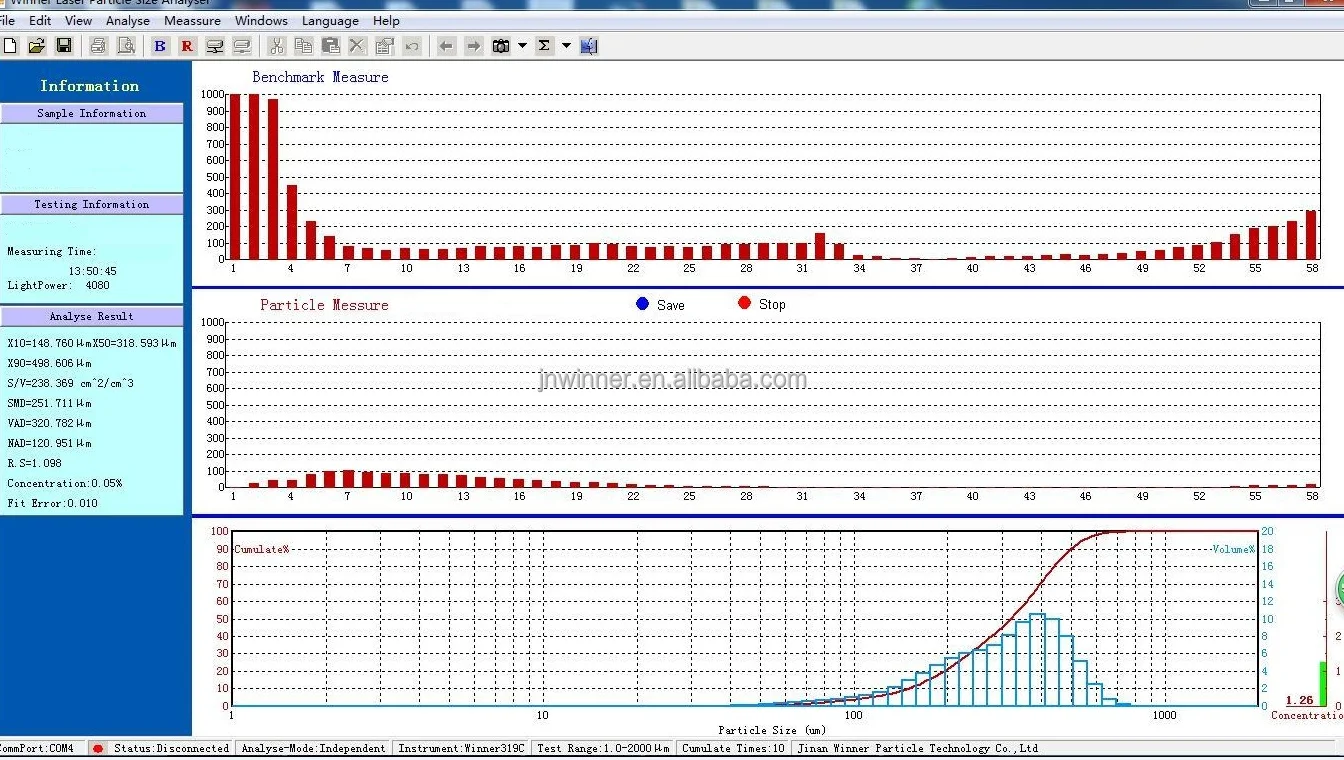

4)Software support

Unique unconstrained free fitting technology make particle analysis not be restricted by any functions, truly reflect particles distribution, ensure accuracy of testing result.

|

Model Name

|

Winner3003

|

||

|

Size Range

|

0.1μm-300μm

|

||

|

Standard

|

ISO13320-1:1999,GB/T19077.1-2008,Q/0100JWN001-2013

|

||

|

Channels Number

|

40 pcs

|

||

|

Accuracy error

|

<1% (Deviation of D50 on national standard sample)

|

||

|

Repeatability error

|

<1% (Deviation of D50 on national standard sample )

|

||

|

Light Source

|

Semiconductor laser (λ= 632.8nm, P>2.0MW)

|

||

|

Dispersion Method

|

Dry-turbulence dispersion mode

|

||

|

Operation Mode

|

Manual / one key test

|

||

|

Optical Path Calibration System

|

manual

|

||

|

Dispersing Medium

|

Compressed air

|

||

|

Test Speed

|

<1min for each time

|

||

|

Operation System

|

Win XP/ Win 7

|

||

|

Connection Port

|

USB

|

||

|

Software function |

Analysis mode

|

Free Distribution, R-R Distribution, Logarithm Normal Distribution, Mesh number classification

|

|

|

Statistic Method

|

Volume Distribution, Quantity Distribution

|

||

|

Statistic Comparison

|

Several Testing Results of samples

Different batches of samples testing result, Samples before and after processing, Test result of samples in different time. |

||

|

User-defined Analysis

|

Figure out percentage according to the particle size

Figure out particle size according to the percentage Figure out percentage according to the particle size range Meet demands of representation of particle test in different industries. |

||

|

Test Report

|

Word, Excel,Photo( Bmp), Text etc

|

||

|

Multi-language Support

|

Chinese&English

|

||

|

Intelligent Operation Mode

|

Automatically control Air flow speed, dispersion,test and analysis.Better Repeatability after remove human-factor

|

||

|

Volume

|

L88cm×W40cm×H30cm

|

||

|

Net Weight

|

36Kg

|

||

We are the 1st manufacturer to produce Nano-particle size analyzer in China.

Our particle size analyzer will enable you understand materials well, and save your time and cost. Reliable data enables scientists, researchers and engineers to evolve formulations and processes with confidence. Our products guide research and product development, manage and control manufacturing quality, and optimize output.

By now, We have Laser Particle size analyzer, Image particle size analyzer, Spray particle size analyzer, particles counter and Nano-particles size analyzer and so on.

We are dedicated to offer you the best particle size analysis solution.

Your satisfaction is our eternal target!

Cooperative Partner

Our Team

We created more than 10 first particle size analysis technology in China!

Quality Assurance

1. Strictly conforming to ISO9001-2000 quality management system.

4.Only qualified components will be assembled and total laser particle size analyzer must be inspected completely before sale.

5.Laser particle size analyzer will be processed preventing -shake test before delivery.

FAQ

1) What materials need test?

If suspension/emulsion, must choose liquid dispersion particle size analyzer, and some materials are also reacted with water, so need liquid dispersion particle size analyzer also. Generally, cement, metal powders and pharamcy materials need dry dispersion model particle size analzyer.

By now, Based on MIE scattering, laser particle size analyzer can test the particle range is 0.01um-2000um.

If materials range is not so wide, for example, 10um-20um, smaller range of particle size distributon choose closer range model will be preciser, no need to buy large range model.

For liquid model, in order that sample can disperse well and circualte in the laser particle size analyzer, generally we need use water, alochol or organic solvent as dispersion media.For dry dispersion model, just use compressed air as dispersion media.In the current market, Dry laser particle size analyzer cost is higher than liquid dispersion models, so if can test well, liquid model is better.

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.